Across National

Time Zones

Precision manufacturing

from coast to coast.

What is Metal Additive Manufacturing?

What is Metal Additive Manufacturing?Metal additive manufacturing, also known as metal 3D printing, is a technology that produces three-dimensional parts layer-by-layer from a powdered metal material, unlike subtractive manufacturing processes which create parts by removing material. The layer build-up of parts offers the ability to manufacture metal parts with complex internal and external geometries in order to save time, avoid wasted material and reduce expenses in the manufacturing process. Metal additive manufacturing can produce complex metal parts from a wide range of materials without the constraints of traditional casting and CNC-based manufacturing processes. Components that would not have been possible to produce with CNC machining can now be made using a wide range of metal powders. Other traditional manufacturing methods like investment casting require tooling that is only cost-effective when large quantities are being manufactured. Additive manufacturing makes it possible to economically produce customized components in smaller quantities.

Metal additive manufacturing has the potential to change the production of components and assemblies. Engineering materials such as stainless steel, aluminum, cobalt chrome, inconel and titanium can be used to create fully dense parts with outstanding properties. Metal additive manufacturing has been used as a prototyping tool for years, but the focus of additive manufacturing is now shifting to serial production. Metal additive manufacturing is now being used for the production of final metal components for a variety of applications in all industries including medical, aerospace, automotive and industrial. Metal additive manufacturing is used to produce end use parts for an increasing number of Fortune 500 Companies who have adopted it as an integral part of their production processes.

A key advantage of metal additive manufacturing is parts consolidation. Because the metal 3D printing process can include intricate and complex designs, multiple parts can be combined into one design, reducing assembly costs. Designers can optimize parts to reduce weight and retain structural strength by including thin-walled components and fine meshes. 3D printing reduces the number of steps from design to finished product to cut time-to-market.

Metal powder bed fusion machines use a high-powered fiber laser to fuse fine metal powders together using a layer melting process. The process requires a 3D Computer-Aided Design (CAD) STL file, which is sliced into layers. For each slice, ultra-fine layers of metal powder are deposited across the build plate. Required areas of the powder are then precisely melted by the laser, which is controlled by the STL file. As each layer cools, it binds to the preceding layer, slowly creating the part from the bottom up. A recoater blade lays new powder for the next slice and the process is repeated until the build is complete. Additive manufacturing systems from EOS can build in a range of metals including titanium, cobalt chromium, stainless steel, nickel alloy, inconel 718 and aluminum.

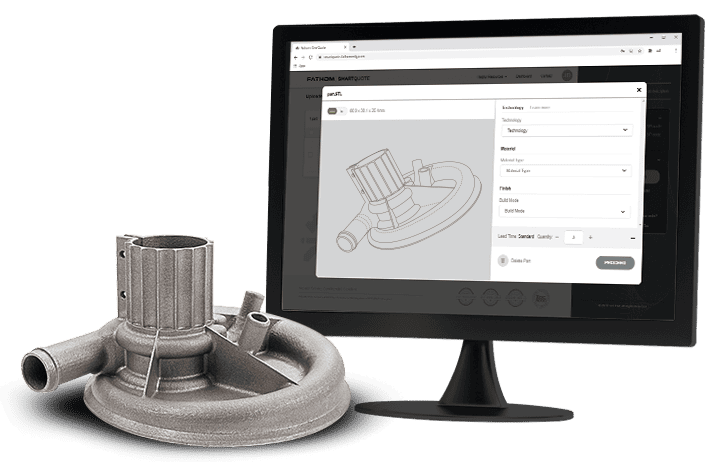

Submit your CAD file to receive a metal 3D printing quote in as soon as one business day.

Precision manufacturing

from coast to coast.

HEADQUARTERS //

1050 Walnut Ridge Drive

Hartland, WI 53029

877-328-4668

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

480-966-2300

CALIFORNIA

46758 Lakeview Blvd

Fremont, CA 94538

COLORADO

7770 Washington St.

Denver, CO 80229

303-288-6855

FLORIDA

14000 N.W. 58th Court

Miami Lakes, FL 33014

305-889-3280

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

815-385-7500

1401 Brummel Ave

Elk Grove, IL 60007

847-952-8088

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

763-755-7575

NEW YORK

1920 Slaterville Rd.

Ithaca, NY 14850

607-277-7070

401 W. Shore Blvd.

Newark, NY 14513

315-331-7680

TEXAS

1513 Sam Bass Rd.

Round Rock, TX 78660

512-255-1477