Aerospace & Defense Manufacturing

Low volume, high-mix part production. Complex geometries. Quick turn-around orders and strict quality requirements. At Fathom, we welcome these types of challenges.

Comprehensive Capabilities for Aerospace & Defense

We’re organized to meet the needs of the world’s leading aerospace and defense companies. We offer one of the broadest platforms of traditional and advanced digital manufacturing technologies and finishing options – all under one roof.

- Need additive metal expertise? We’re one of the largest producers of direct metal laser sintering (DMLS) parts in North America.

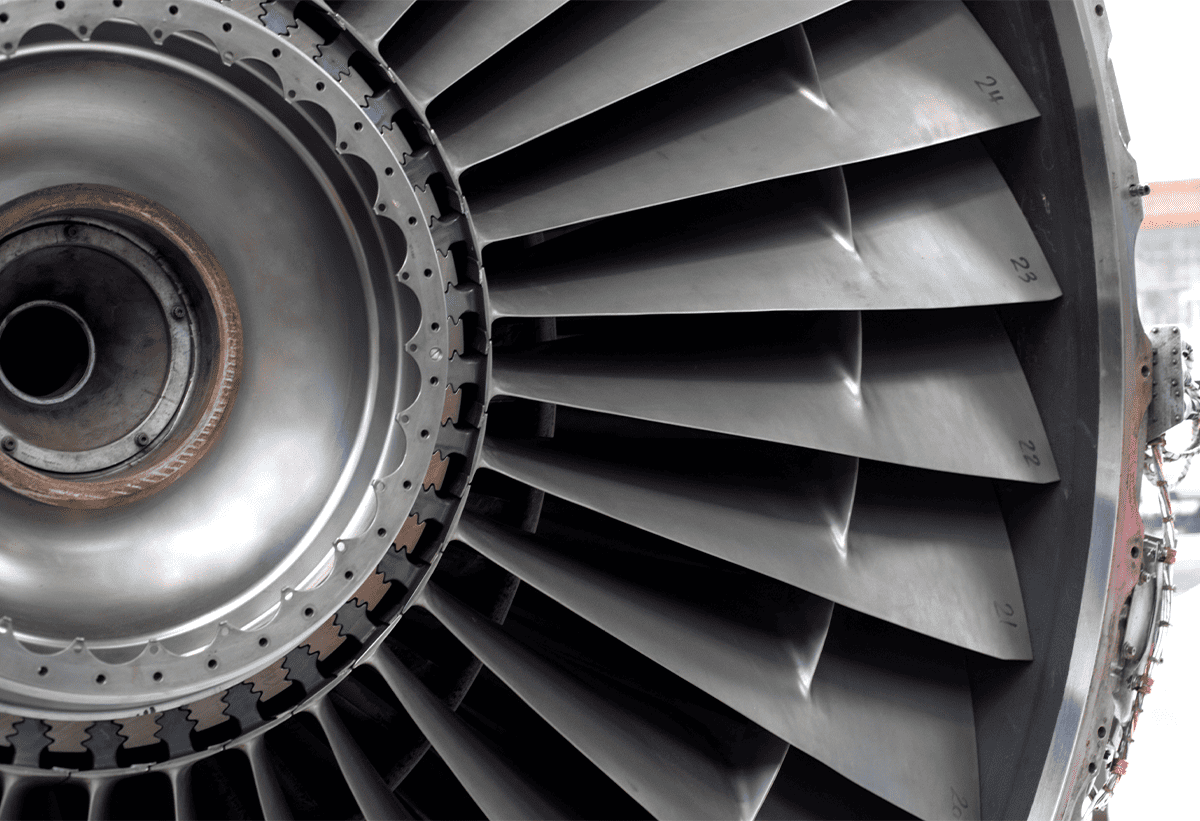

- Need sophisticated metal forming and machining capabilities of the world’s toughest materials? We’re experts at it.

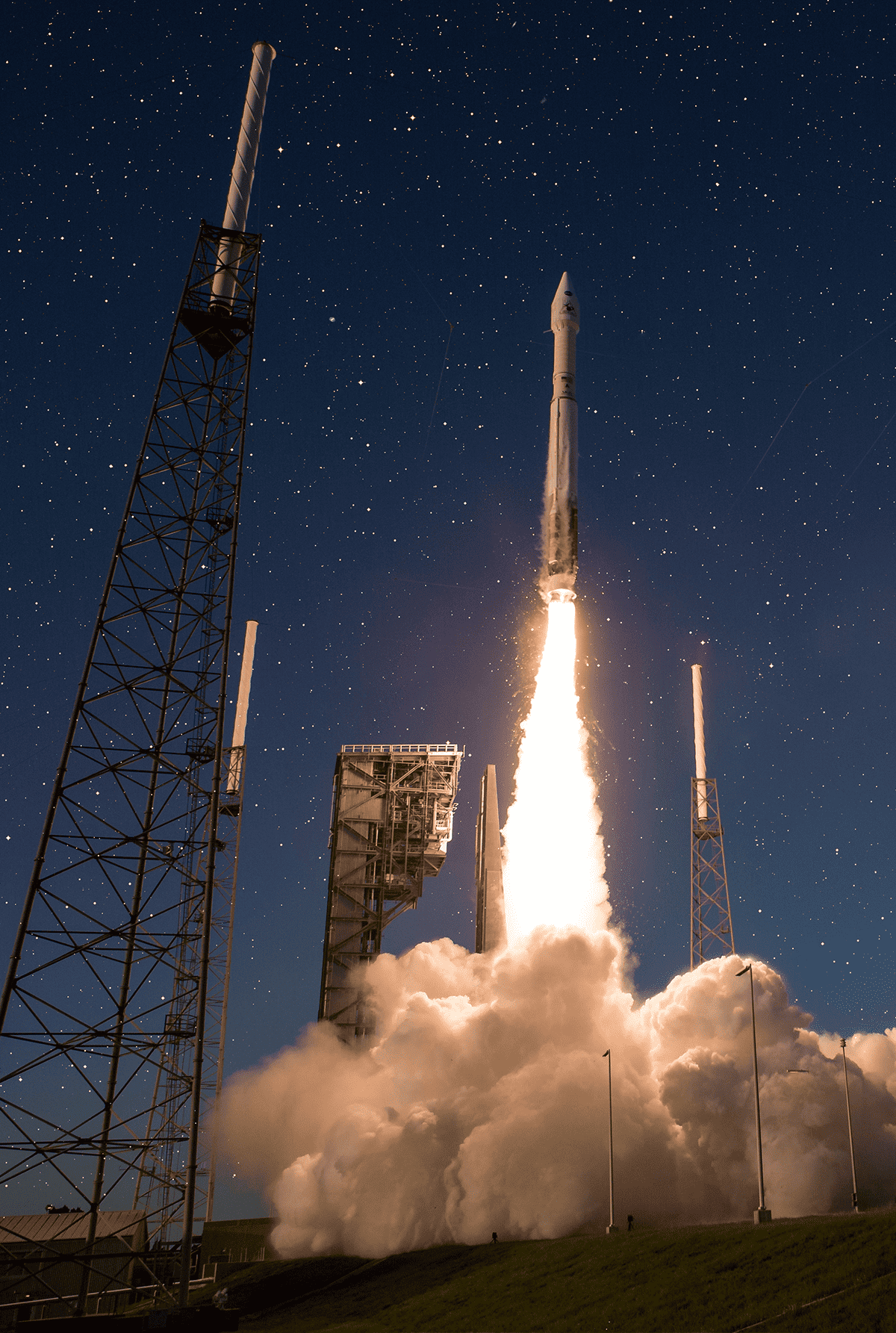

- Need expertise on the environments where your parts must perform? We can help you, whether they’re used on the ground, in the air or space.

Our business is uniquely configured to help you:

- Refine your component concepts into prototypes,

- Optimize your part designs, material selection and production processes for optimal results, and

- Move them into bridge production, short-run production or full production.

How Can Fathom Help You With Your Aerospace & Defense Part Needs?

From the moment you contact us, you’ll be talking with an engineer, who will work closely with you to understand your needs. For example, we take a hands-on, personalized approach to DFMs to ensure that all potential problems are identified and solved early in the product development process.

We’ll help you optimize your part design, production process and material selection for the best results, at the best price. Our experienced engineers can help you confidently move your projects from prototype to production.

With over 25 manufacturing methods and 11 locations, we’re technology-agnostic. We’ll guide you to the solution that makes the most sense for the demanding environments in which your parts must perform. In short, we can help you accelerate your product development cycle.

We also have years of experience meeting the world’s most demanding aerospace and military specifications.

Technologies for the

Aerospace & Defense Industries

Additive Manufacturing

Additive metal technology, such as Direct Metal Laser Sintering (DMLS), is an ideal fit for the high-performance, lightweight needs of the aerospace and defense industries. Fathom can also produce rugged plastic parts using additive technologies like Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF).

Many of these methods can be used to produce prototype parts for check fit, finish and functionality. In some cases, they can also be used to produce bridge and limited-run production parts. We also offer multiple finishing options for additive parts. Including post-machining, painting and advanced coatings.

STEP Technology

Exclusively available from Fathom, Selective Thermoplastic Electrophotographic Process (STEP) enables the additive production of tough, durable, high-precision thermoplastic parts at injection molding speeds. It’s ideal for prototyping and bridge production of parts for the aerospace and defense industries.

Injection Molding

Injection molded parts are used throughout today’s aircraft. Durable, high-performance plastics are used to produce interior components, such as overhead luggage compartments and lighting systems.

Sheet Metal Fabrication

Fathom can handle your large sheet metal needs as well as precision forming of small, complex metal components and photo chemical etching, used to produce extremely flat, burr-free parts.

CNC Machining

Our facilities do some of the most advanced, precise CNC machining work in the country, including tough materials like aluminum, titanium and Inconel.

Aerospace and Defense Applications

- Aircraft interiors

- Spacecraft and satellite components

- Telecommunications components

- Optical system components

- Military rifle components

- Military vehicle components

- Military UAV and drone components

- High-performance tools and fixtures

Quality is Priority #1

At Fathom, our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing.

In addition, we have a proven ability to comply with customer-specific process, material and workmanship standards.

Certifications

- AS9100

- ISO 9001:2015

- NIST 800-171

- ITAR

Why Choose Fathom?

- We understand the environments that your parts are exposed to, from the ground and air to space.

- We have the certifications and technical experience to be able to deliver high-performance, cost-effective parts that meet your requirements.

- We can support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes to verify fit, finish and functionality as well as bridge production and full production.

- We offer an unmatched breadth of manufacturing technologies – in-house, not via third parties – to meet all of your needs, including additive manufacturing, injection molding, sheet metal forming and precision CNC machining.

- We have a long track record of success delivering high-quality parts to a variety of aerospace companies, military agencies and other organizations that serve these cutting-edge industries.

- We’re problem solvers. Bring us your complex geometries, short-run/high-mix parts and “impossible” projects. We’ll help you get the work done!