Direct Metal Laser Sintering //

DMLS 3D Printing

- Get High-Quality Metal Parts Fast – Without Tooling

- Perfect for Prototype, Bridge and Low-Volume Production Parts

- Complex Geometries with High-Performance Metals

Get a Quote

Or Any of Our 25+ Manufacturing Processes

Get Complex Metal Parts Fast

with Direct Metal Laser Sintering (DMLS)

Ideal for Prototype Parts and Bridge Production

Are you developing a new product? Are you under pressure to bring it to market quickly? Do you need to validate the fit and finish of a metal part, but aren’t ready to have expensive tooling and fixtures made?

DMLS is a metal additive manufacturing technology that can help you solve this problem and accelerate your time to market. It’s perfect for:

- Prototype parts

- Bridge production while you’re awaiting your production tooling

- Low- to medium-volume production parts

- Complex metal part designs that can’t be produced any other way

- Situations where you need metal parts – fast!

DMLS Parts in as Soon as 3 Days // Get A Quote

How Does Direct Metal Laser Sintering Work?

A metal 3D printer utilizes a laser beam to melt 20- to 60-micron layers of metal powder on top of each other. Powdered metal is spread across the entire build platform and selectively melted to previous layers. This additive process allows metal parts to be grown out of a bed of powdered metal.

The result is a high-quality metal part that doesn’t require sintering and has the mechanical characteristics of cast metal parts. Fewer steps equal faster production – usually 5 days or less.

Because no tooling is required, parts can be produced at a fraction of the cost of custom steel tooling and fixtures.

Applications of DMLS

Functional Prototypes // Produce and iterate prototype part designs quickly – without the expense of tooling.

Jigs and Fixtures // The exceptional toughness of DMLS parts makes them ideal for jigs and fixtures for CNC machining, part inspections and more.

Flow Applications // Certain part designs require channels for fluid or air to pass through. This includes conformal cooling channels, which run just below the surface of the part. They can’t be machined into parts but are easy to create using 3D printing with DMLS.

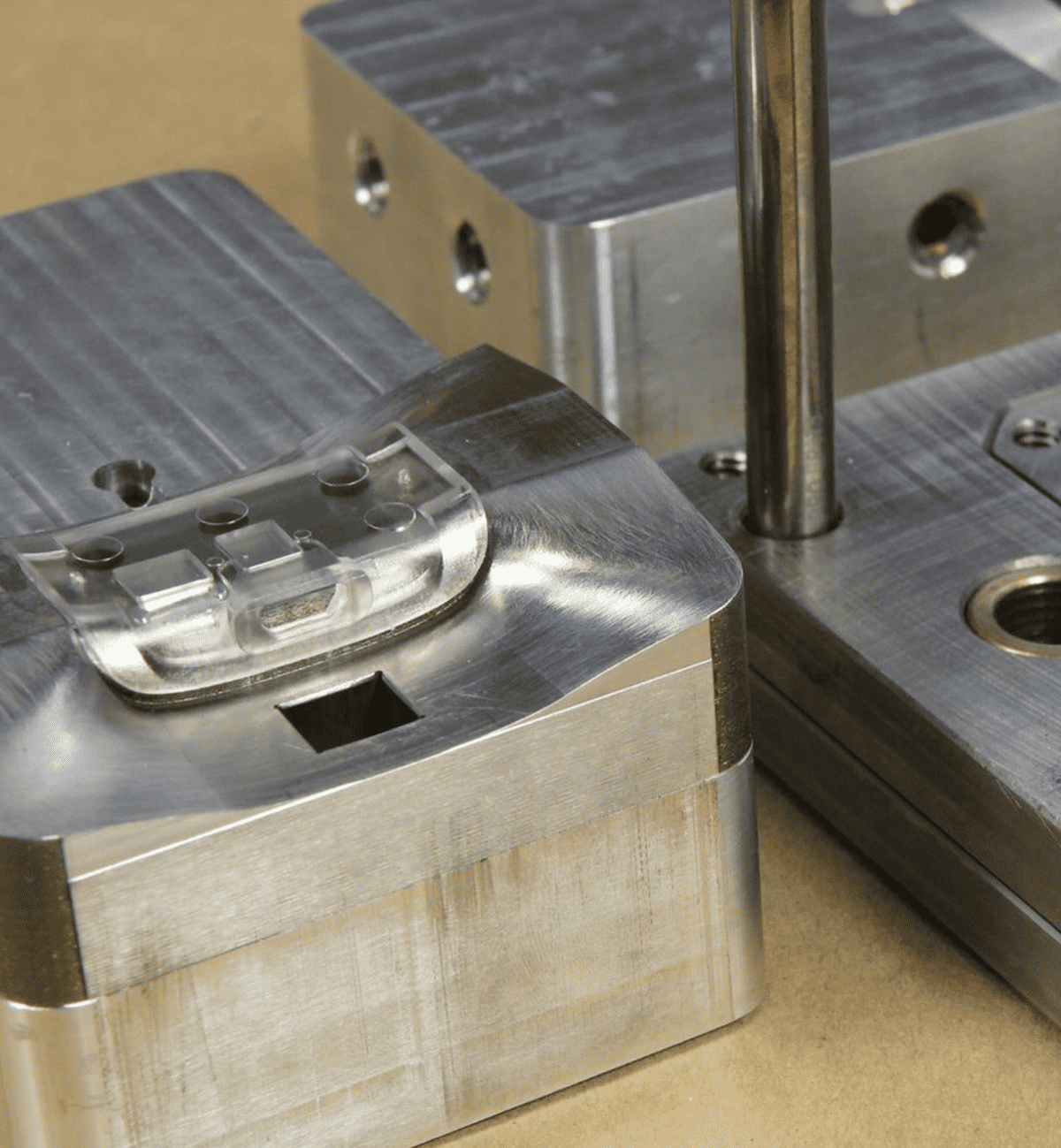

Fast Metal Tooling for Injection Molding // DMLS can be used to build short production-run tooling for injection molding.

Industries where DMLS parts are used include:

- Aerospace

- Medical

- Dental

- Automotive

What Does DMLS Make Possible?

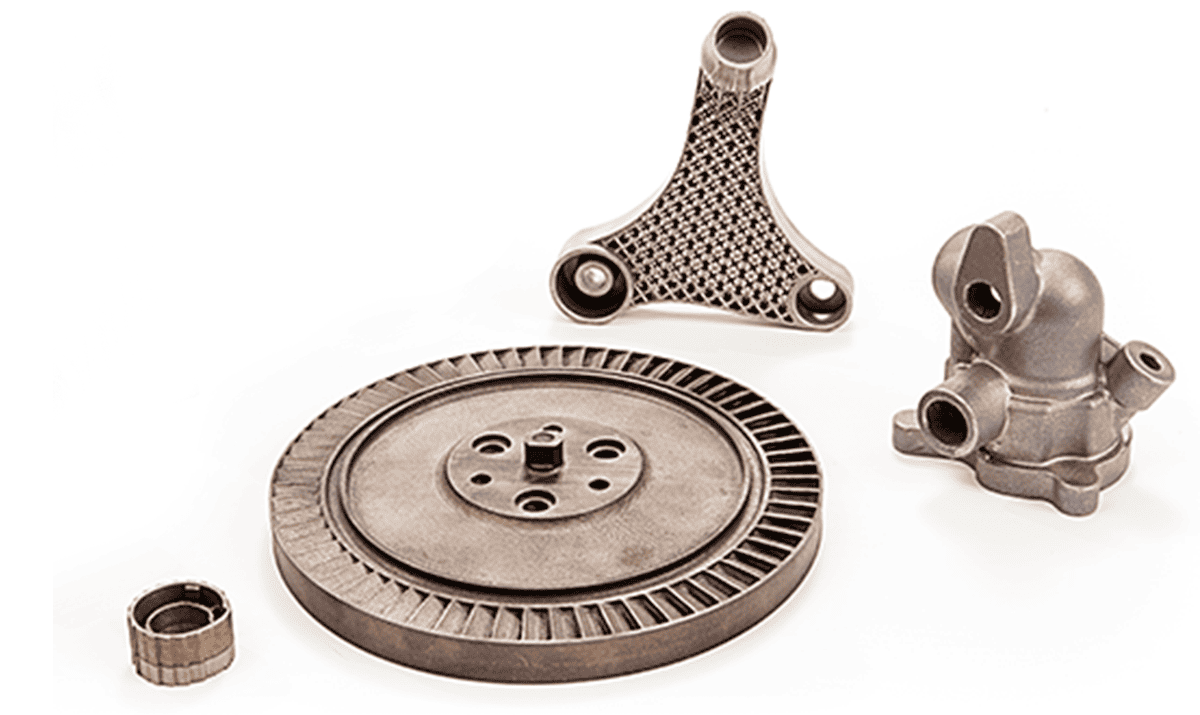

Design Freedom // Subtractive manufacturing techniques place limits on what you can create. DMLS enables you to produce part designs that are difficult or impossible to achieve with traditional manufacturing techniques, such as:

- Internal supports

- Weight-saving lattice wall sections

- Conformal cooling channels

- Undercuts

- Draft angles

- Internal cavities

- Varying wall thicknesses

Part Consolidation // Thanks to the design freedom that DMLS enables, you can consolidate assemblies into a single, printable part that is lighter, less expensive and more reliable.

Fast Prototyping // DMLS empowers you to iterate your prototype part designs quickly – without the need for costly tooling. You can also use it to print multiple variations of a part at the same time to determine which one offers the best functional design.

Production Parts // Need bridge production? You can use DMLS to produce several hundred production-quality parts quickly so you can keep your production line running while you wait for tooling.

Advantages

Complex Geometries // DMLS can print complex part designs that aren’t possible to fabricate using traditional methods. Engineers are also free to design complex parts without the need for support structures.

Excellent Mechanical Properties // The sintering process used with DMLS produces parts that are strong and durable. They exhibit high tensile strength, hardness and wear resistance, making them suitable for demanding applications in the automotive, aerospace and medical industries.

Mass Customization // No fixtures or tooling are required to produce DMLS parts. That makes it easy for engineers to modify or fine-tune part designs during production. It also enables designers to create multiple variations of parts as needed.

Metal Characteristics are Preserved // The sintering process used to transform metal powder into parts bonds them without melting the metal. That means its mechanical properties remain intact after the part is produced.

Disadvantages

Small Build Volume // As a platform for additive manufacturing, the build volume of DMLS is on the smaller side. It’s best for producing small parts.

Post Processing // Depending upon the part and its application, DMLS parts may be post-processed using heat treatment, surface finishing and machining.

Expertise // As a technology, DMLS is a complex additive manufacturing process that requires expertise to consistently produce high-quality parts, and a detailed DFM/DFAM analysis is critical to success. However, Fathom is one of the largest and most experienced service bureaus in North America for DMLS parts and can be trusted with your DMLS production!

What Can DMLS be Paired With?

DMLS parts are dense and have similar mechanical properties to cast parts. Where tight tolerances are required, DMLS parts can be 3D printed at a near-net shape and then machined to meet them.

Once a part has been produced using DMLS, it can be improved using processes that are common to finishing metal parts, including media blasting, metal plating, micromachining and polishing. Holes or threads may be added to parts using CNC machining.

Titanium is notoriously hard to machine. For aerospace applications, where light weight and strength are a must, DMLS can be used to produce strong, lightweight parts using this exotic material.

Alternatives to DMLS

Metal injection molding

Selective laser melting

Laser deposition welding

Traditional Technologies That Can Benefit from DMLS

Direct Metal Laser Sintering can be used to build complex part designs that aren’t possible using traditional manufacturing methods such as CNC machining and metal casting.

DMLS also enables fast, low-cost production of prototype and production parts – without tooling.

In addition, DMLS enables designers to combine multiple machined or cast parts into a single component that is stronger and lighter than the assembly it replaced.

Finally, DMLS can replace casting or machining of low-volume replacement parts, which usually require costly set-up time, fixtures and labor. Instead, they can be printed on-demand as needed, reducing or eliminating the need to maintain an inventory of service parts.

DMLS Materials Available

Common materials used to produce DMLS parts include:

- Aluminum

- Maraging steel

- Stainless steel

- Titanium

Not sure what you need? Talk to a Fathom expert today!

Finishing Options for DMLS Parts

Fathom offers a multitude of in-house finishing options for DMLS parts. Our experts can also manage any of your outsourced finishing needs.

Parts built on a DMLS machine have a raw, rough finish comparable to a fine investment cast. The surface roughness is approximately 350 R a- µ inch or R a-µm 8.75, or a medium-turned surface. This surface roughness can be improved all the way up to 1 R a- µ inch or R a-µm 0.025, qualifying as a super mirror finish.

Talk to an expert at Fathom today to discuss your DMLS post-processing needs.

Multiple processes can be used to achieve the desired surface roughness or finish, including:

- Abrasive blast (grit and ceramic)

- Shot peen

- Optical polish

- Electrochemical polishing

- Abrasive flow machining (extrude hone)

- Electroplating

- Micro machine process (MMP)

- CNC finishing/machining

Why Choose Direct Metal Laser Sintering?

Prototype to Production

Produce high-quality prototype, bridge or production parts with excellent mechanical properties – without the expense of tooling, jigs and fixtures.

Complex Designs

Build complex part designs that cannot be manufactured with conventional metalworking technologies.

Problem Solving

Achieve your goals for part consolidation and weight reduction that can’t be met any other way.

Why Choose Fathom’s DMLS 3D Printing?

Fathom has the expertise and technology to help you meet your needs faster.

Fathom has numerous DMLS printers, making it one of the largest service bureaus for this metal additive manufacturing technology – with deep DFAM and production expertise to match.

We also offer a wealth of post-processing capabilities under one roof – which can save you time and money.

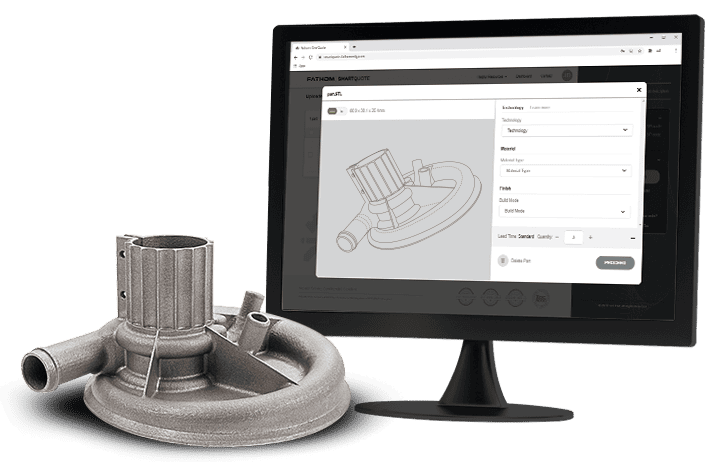

Get a quote on your DMLS project today with our SmartQuote platform.