CNC Machining

- Comprehensive Machining Capabilities

- Unmatched Depth of Expertise

- We Take on Challenging Jobs

Get a Quote

Or Any of Our 25+ Manufacturing Processes

Precision and Speed

for Your Most Demanding Applications

Do you have unique machining needs? Complex part geometries? Tough materials? Extremely tight tolerances? We take on challenging jobs like these every day – projects that other shops back away from. Here at Fathom, it’s one of our core competencies.

If you’re looking for a firm that can keep up with your needs and lead your thinking, then it’s time to take a closer look at Fathom’s comprehensive CNC machining capabilities.

How Does CNC Machining Work?

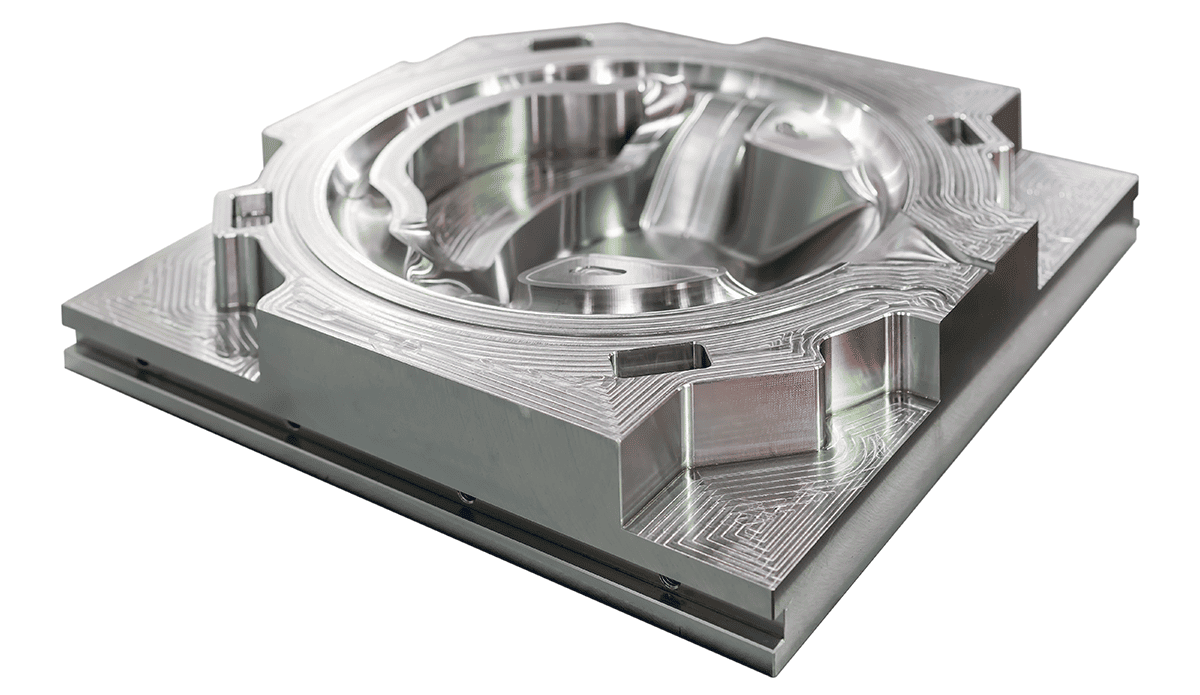

CNC machining is a subtractive manufacturing process that utilizes computerized controls and machine tools to remove layers of material from a blank to produce a custom-designed part using drilling, milling and turning operations.

CNC Drilling // Drill bits are used to make cylindrical holes in the workpiece. Normally, these holes are perpendicular to the surface of the workpiece. But specialized tooling also enables the drilling of angular holes. Other common drilling operations include counterboring, countersinking, reaming and tapping.

CNC Milling // Three-axis milling machines can cut three surfaces of a part along its X, Y and Z axes. A 5-axis mill adds two rotational axes to give machine tools access to five out of six part sides without the operator needing to reset the workpiece.

CNC Turning // Material is removed from a workpiece as it is being rotated at high speed on a lathe. It’s commonly used to create cylindrical parts. Common operations include cutting slots, tapers and threads into its surface. Boring, facing and grooving can also be performed.

Swiss Screw Machine // This is a specialized type of lathe that enables the workpiece to move back and forth as well as rotate. This enables tighter tolerances for the most demanding applications.

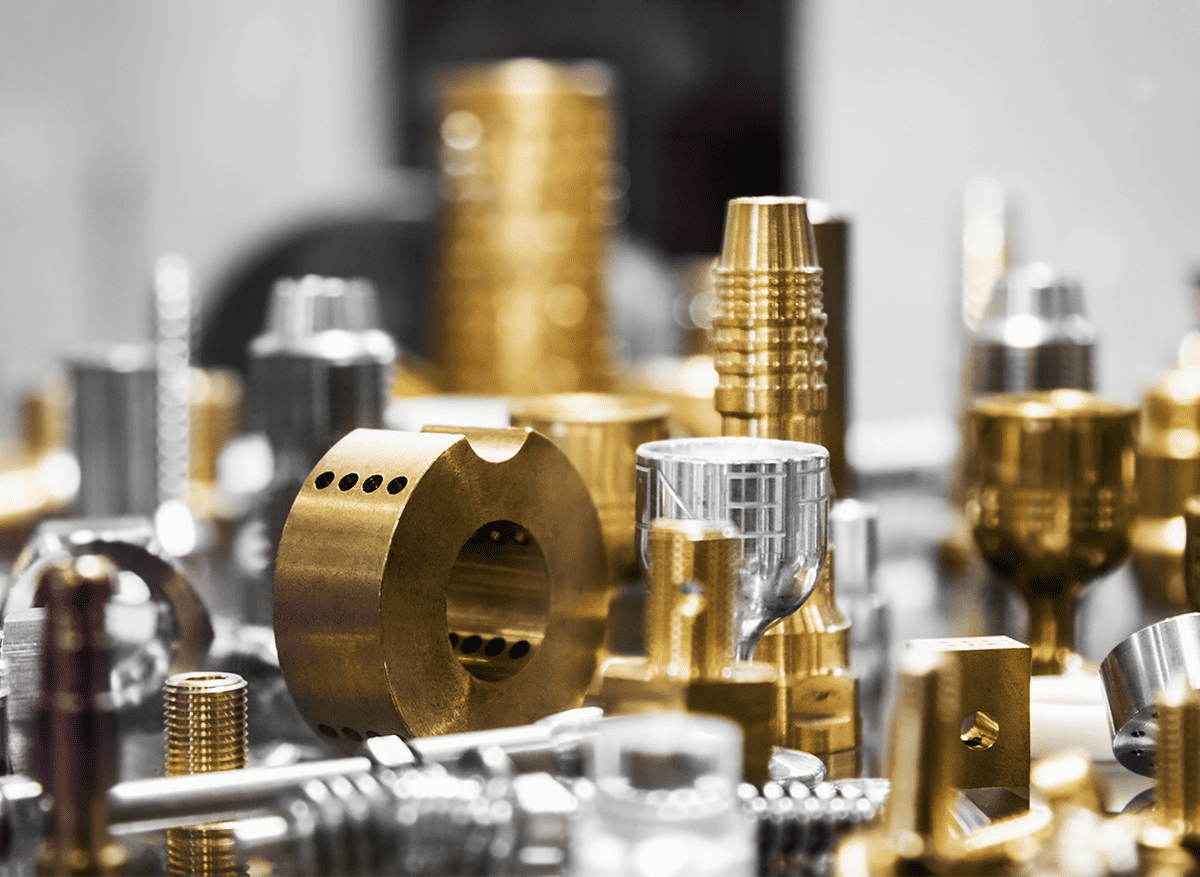

CNC machining can be done with many types of material, including metal and plastic.

Applications of CNC Machining

The applications of CNC machining are nearly limitless. CNC machining can be used to produce a wide range of parts from a variety of materials. Fast turnaround times, efficient manufacturing and ease of use make CNC machining the ideal choice for prototyping and low volume production runs. CNC machining is commonly used in aerospace, automotive, consumer, industrial, medical, and technology sectors.

Aerospace // CNC machining is widely used in the aerospace industry. Aerospace applications require extremely precise and lightweight parts. CNC machining is capable of producing these parts in a variety of materials.

Automotive // Like the aerospace industry, the automotive sector also values parts that are precise and lightweight. CNC machining is used for automotive prototyping and production. Metal can be machined for various components including gear boxes, cylinders, and axels. Plastic can be machined for interior components for the dashboard, gauges, and trim.

Consumer // CNC machining is widely used for prototyping and production of consumer products. Both metal and plastic are produced for consumer products. CNC prototyping is an excellent way to provide physical examples for investors and advance marketing. Examples of CNC machining in consumer products includes housing, fixtures, and components. A popular example would be the bodies of some cell phones and laptop computers. These are typically machined out of aluminum.

Industrial // CNC machining is widely used for industrial purposes, both as a manufacturing method in itself and as a way to create components to aide industrial manufacturing. CNC machining is a mainstay in industrial manufacturing due to its ease of use, repeatability, and precision.

Medical // CNC machining is used in the medical sector to create components for medical devices and medical implants. CNC machining in plastic is used to create components for medical devices. CNC machines can work with a variety of materials that have been approved for close contact with the human body. CNC machining is an easy way to prototype medical devices before moving to full production. CNC machines can work with the same materials that are used in injection molding. CNC machining in metal is an ideal manufacturing method for creating medical implants. CNC machines offer the precision and repeatability necessary to manufacture medical implants. Examples include replacement hips and kneecaps, screws, pins, and rods. Fathom Digital Manufacturing is ISO 13485:2016 certified. This certification is required to machine medical implants.

Technology // CNC machining is widely used in emerging technology sectors for prototyping and small production runs. Fast turn around and low cost set up make CNC machining an ideal manufacturing technique for the fast-paced technology sector. CNC machining can be used to create prototypes to show potential investors and help raise venture capital. Design reiterations are easy to implement with simple changes to the CAD file.

What Does CNC Machining Make Possible?

Rapid Prototyping // Parts can be CNC machined in a matter of hours, making it easy to iterate part designs and accelerate time to market.

Fine Details and Tight Tolerances // CNC machining can be used to produce complex parts with tight tolerances.

Excellent Accuracy and Repeatability // Because the machine tools used in this process are computer-controlled, they can be used to produce a large number of parts with a high degree of accuracy. That’s why it’s a preferred manufacturing method for high-performance industries like automotive, aerospace and defense.

Advantages

Produce Parts to Precise Specifications // It can be used to produce simple parts with high precision and high accuracy, with tighter tolerances than injection molding or additive manufacturing.

Ideal for Prototype Parts // CNC machining can be used to quickly produce accurate prototype parts in a matter of hours.

Versatility // CNC machining can be used with a wide variety of materials, including all types of metals and alloys, plastics, phenolics and rigid foam. It can be used to produce everything from prototype and short-run parts to bridge production and large production runs.

Scalability // Once a CNC machine is programmed and set up to run a job, it can continue to produce that part 24 hours a day. Each part will have identical accuracy and precision

Disadvantages

Set-Up Time // Workpieces typically require fixtures and jigs to securely position and hold the part while machining operations take place. This work can be time-consuming and requires significant operator expertise.

Cost // CNC machining tends to be more expensive than some other types of manufacturing.

Part Geometry Limitations // CNC machining can’t be used to create cavities within parts or conformal cooling channels, because there’s usually no way to get a cutting tool inside of a part. Large parts may also be challenging to produce using CNC machining.

Key Considerations

When Designing for CNC Machining

Work Holding // The geometry of the part will dictate how it will be positioned on the CNC machine and the amount of setup required. Manually repositioning a part can increase the chance of error. Repositioning will impact not only accuracy but may increase the cost of the project.

Tool Stiffness // The tool used to cut the part may vibrate during operation. Tool stiffness may result in loose tolerances.

Work Piece Stiffness // Temperatures and cutting forces that arise during machining may cause the work piece to vibrate, resulting in deformities. Prevent work piece stiffness by ensuring the design specifications call for the minimum wall thickness and a maximum aspect ratio of tall features.

Tool Geometry // CNC machine cutting tools have a cylindrical shape and a flat or rounded end. This can restrict the possible geometry of CNC machined parts. The inside vertical corners of the part will have a radius, even if a small cutting tool is used. Sharp inside corners may be difficult to achieve.

Tool Access // The work piece cannot be machined if the cutting tool is unable to reach a surface. This places a limitation on parts that require hidden, internal geometries and sets a limit on the maximum depth of an undercut. Consider metal 3D printing using Direct Metal Laser Sintering (DMLS) for parts with complex geometries, internal cavities, and deep undercuts. DMLS is capable of producing high-density metal parts in a variety of materials.

What Technologies Can CNC Machining be Paired With?

Some types of manufacturing methods, such as injection molding and certain types of additive manufacturing, are efficient and can produce parts that meet most of the customer’s specifications. However, they may not be able to hold the tight tolerances that the application requires.

In cases like these, parts can be created with machinable surfaces that can then be milled or turned to achieve the tolerances required.

Alternatives to CNC Machining

While CNC machining is appropriate for creating many types of parts, it does have some limitations. For example, it can’t be used to create internal features such as internal cavities or conformal cooling channels. These are easily made using additive manufacturing methods like DMLS.

For certain types of flat workpieces, laser cutting, water jet cutting, wire EDM cutting, photo chemical etching or metal additive manufacturing may be more efficient.

CNC Materials Available

For a complete inventory of metal and plastic materials, sizes and tolerances, please download our CNC material sheet.

Not sure what you need? Talk to a Fathom expert today!

Post-Processing & Finishing Options

Post processing is an easy way to ensure a uniform appearance from part to part. Some CNC machines, like the CNC mill, may leave visible tool marks on the piece after production. Tool marks may vary from slight to obvious, depending on the material and CNC process. Post processing is available for plastic and metal parts. This can include bead blasting to remove tool marks, or painting to achieve a desired color.

Finishes for Metal //

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Finishes for Plastic //

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

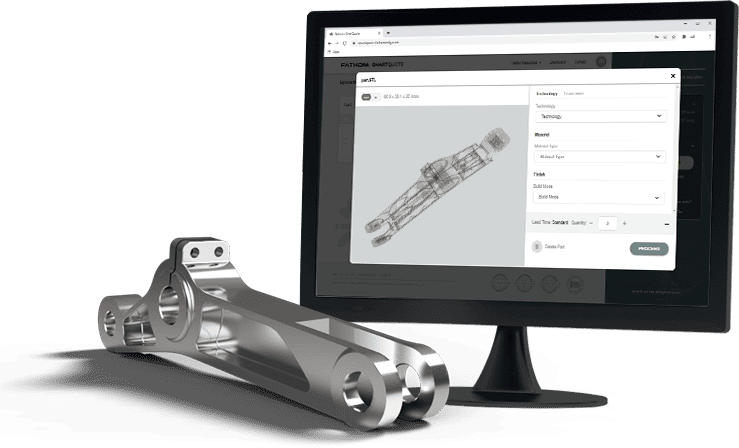

Why Choose Fathom’s CNC Machining?

Fathom has the expertise and technology to help you meet your needs faster.

Fathom has an unmatched depth of expertise in CNC machining and the capacity to take on your projects. Our CNC facilities specialize in challenging applications, like working with extremely tight tolerances and exotic materials for use in medical or aerospace industries, for example. We even work with specialized materials like Inconel and Monell, two of the world’s toughest alloys.

Fathom also has certifications at several of our locations to meet the highly specialized needs of your medical, aerospace or government industries, including ISO 13485, AS9100 and ITAR. View our certifications by location →

Our Fathom Experts recognize the value of having design and manufacturing collaboration at any stage in the product development process, and a DfM analysis is available with every quote. Our diverse group of engineers, designers and builders help you navigate the right process, materials and more for each stage of your product development – from design and prototype, to validation for mass-production.

Additional Resources